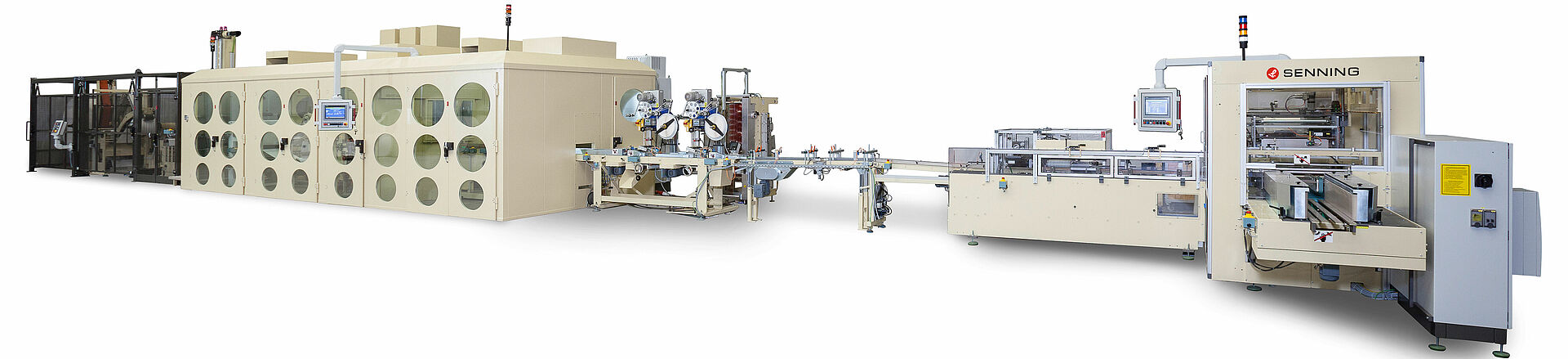

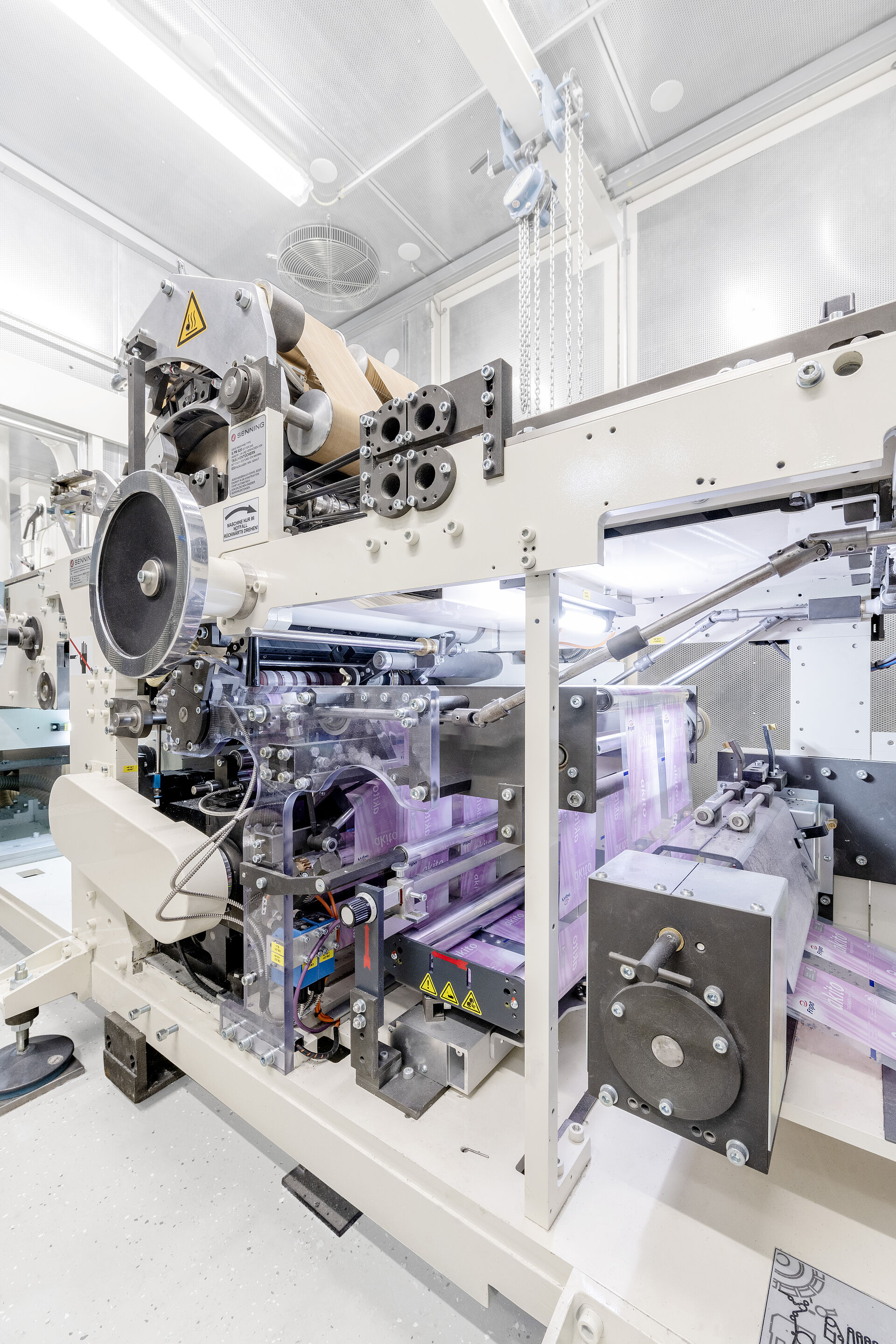

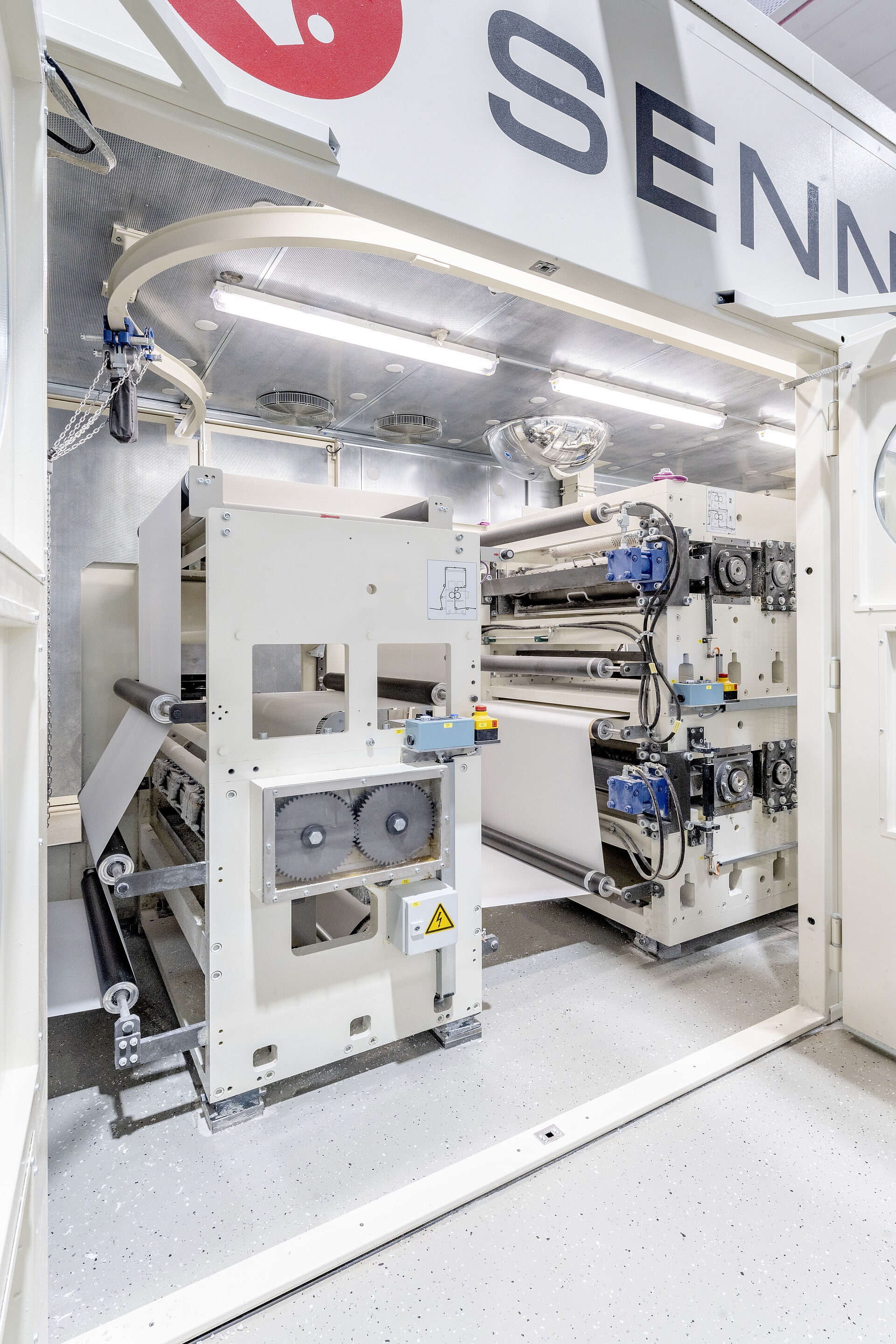

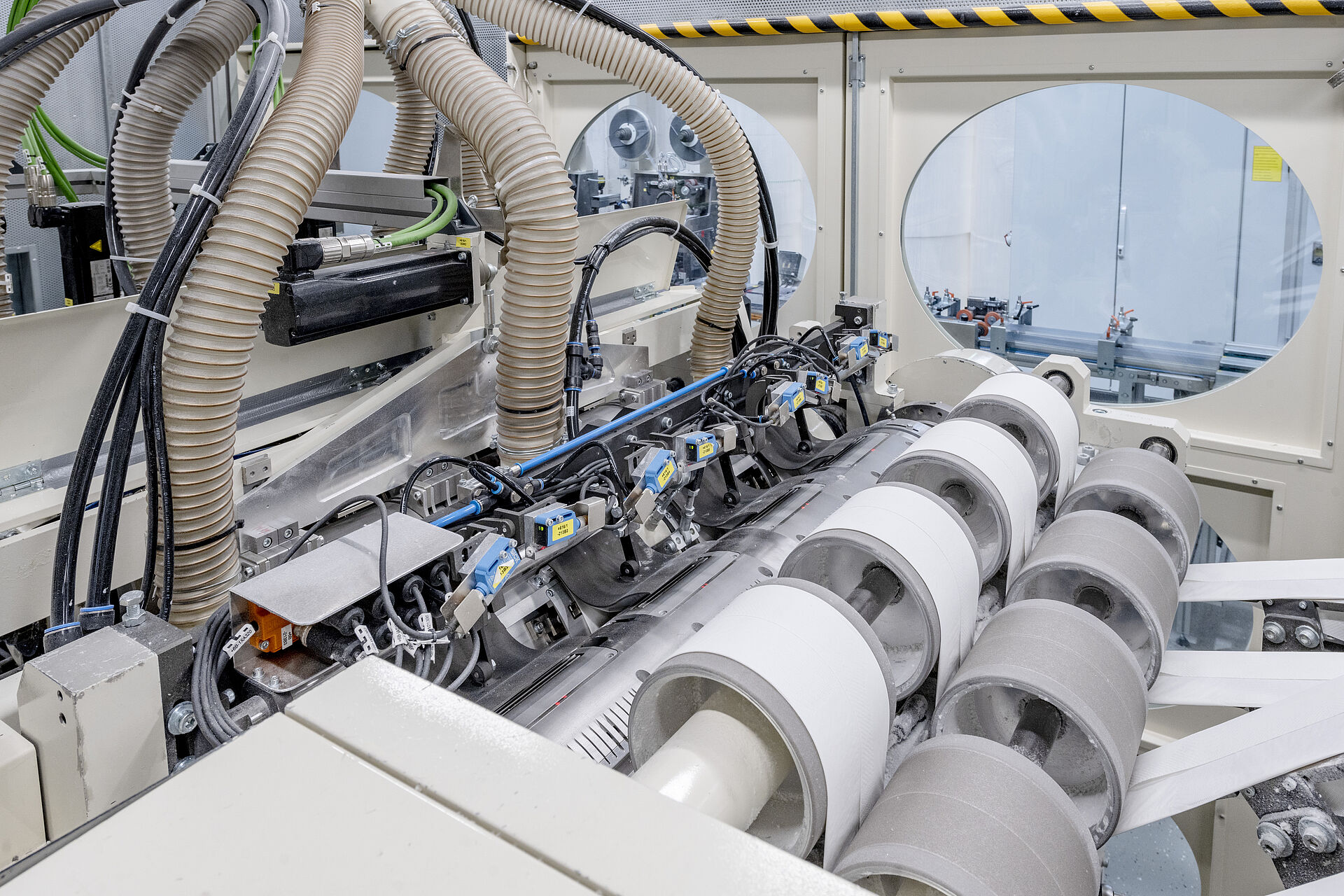

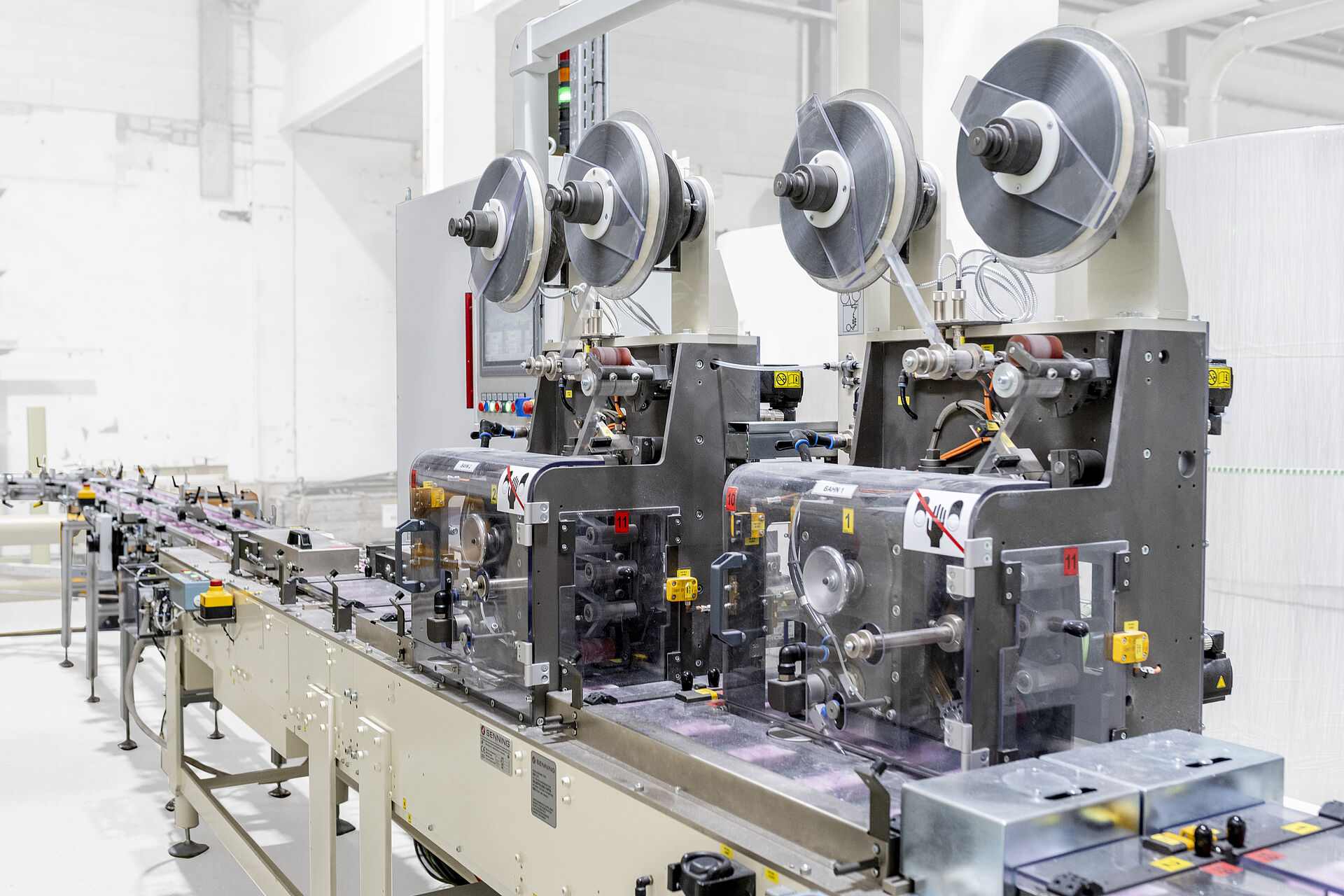

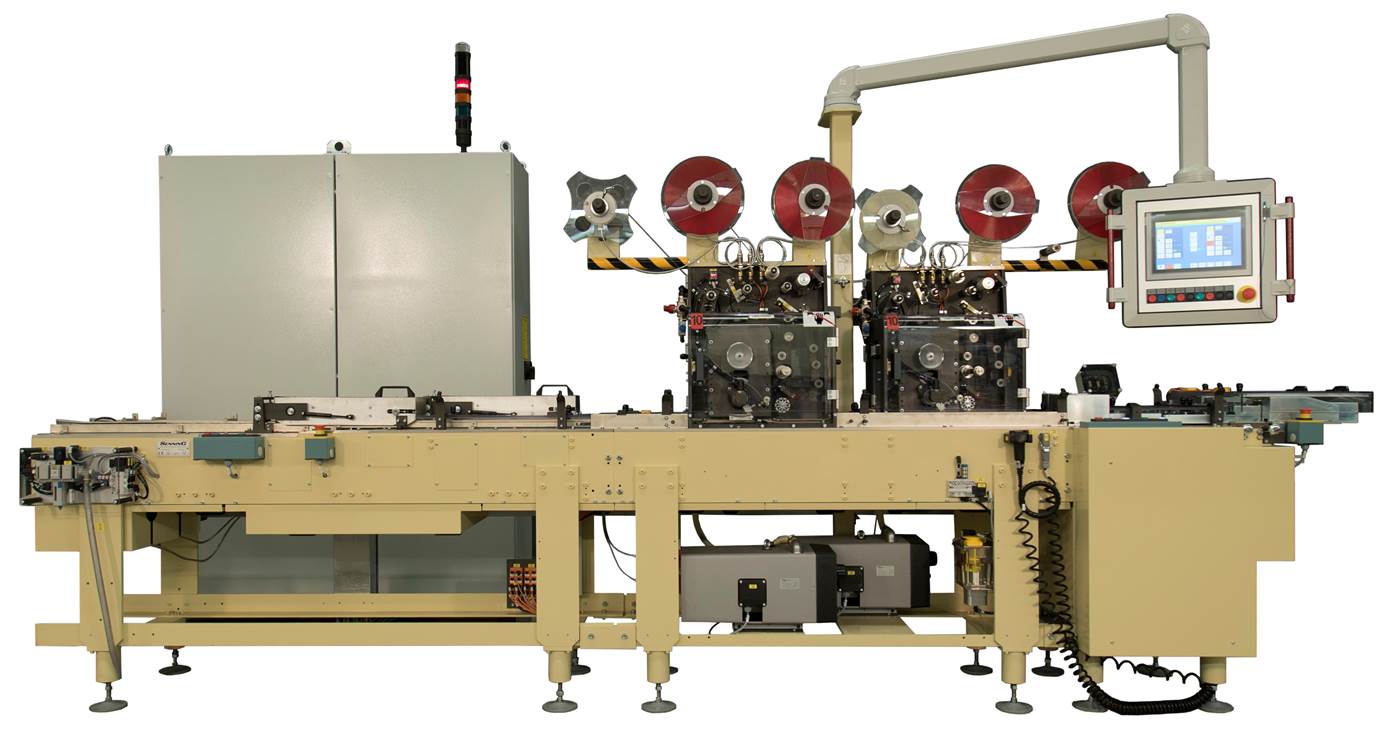

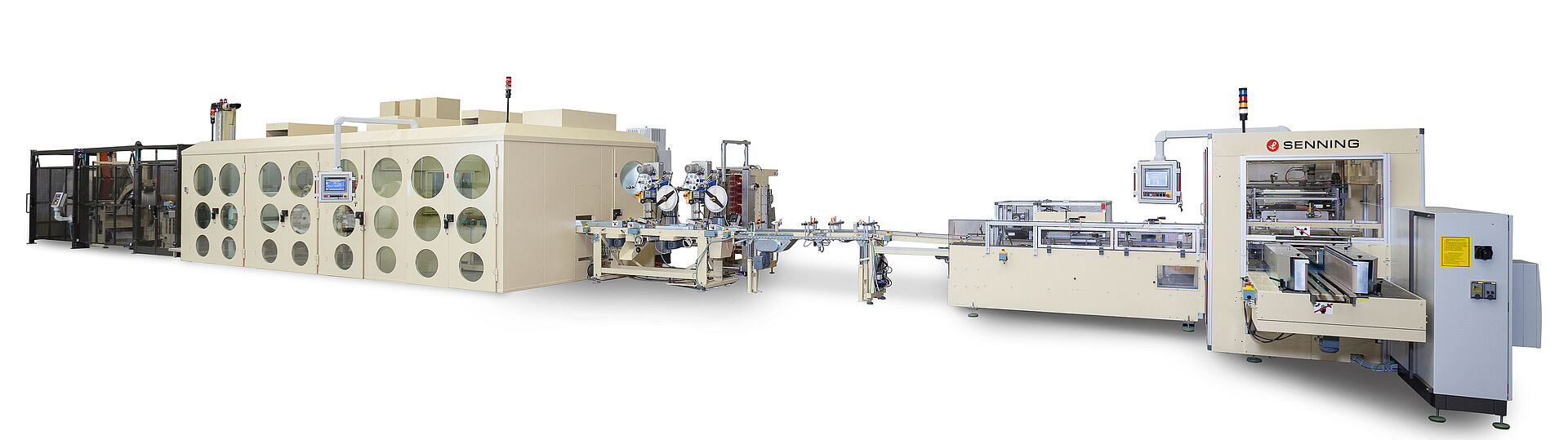

Due to our long-term experience, all our sections are well coordinated with each other so that they intermesh perfectly. Thus, operation, maintenance and upgrading can be carried out flexibly. Inline positioning guarantees an optimum material feeding. For high efficiency and high profitability.